OUR SERVICES

Restoration

At LMC, we bring classic vehicles back to life with precision, passion, and craftsmanship. Whether it’s a complete motorcycle or car, or individual components such as engines, frames, or smaller parts, we provide restoration solutions tailored to your needs.

Our services include full and partial restorations:

- expert mechanical repairs

- bodywork

- custom paint

- detailing

- authentic parts sourcing.

- glass blasting

- replating

- welding

- etc.

As well as restomod upgrades for clients seeking modern performance and comfort in a classic design.

From small repairs to complete rebuilds, we deliver results that blend traditional craftsmanship with modern expertise — restoring or reinventing your ride with exceptional quality and care.

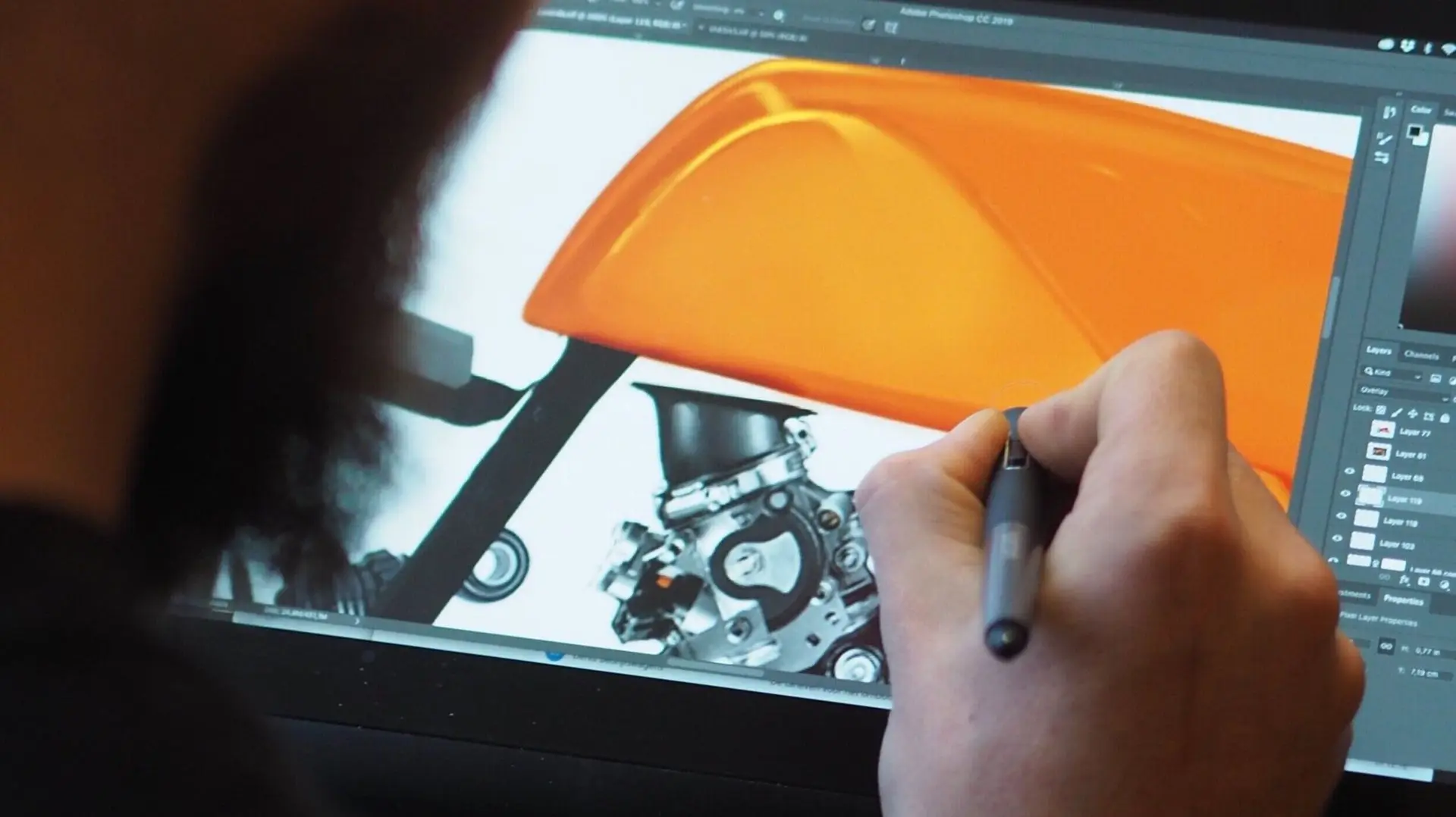

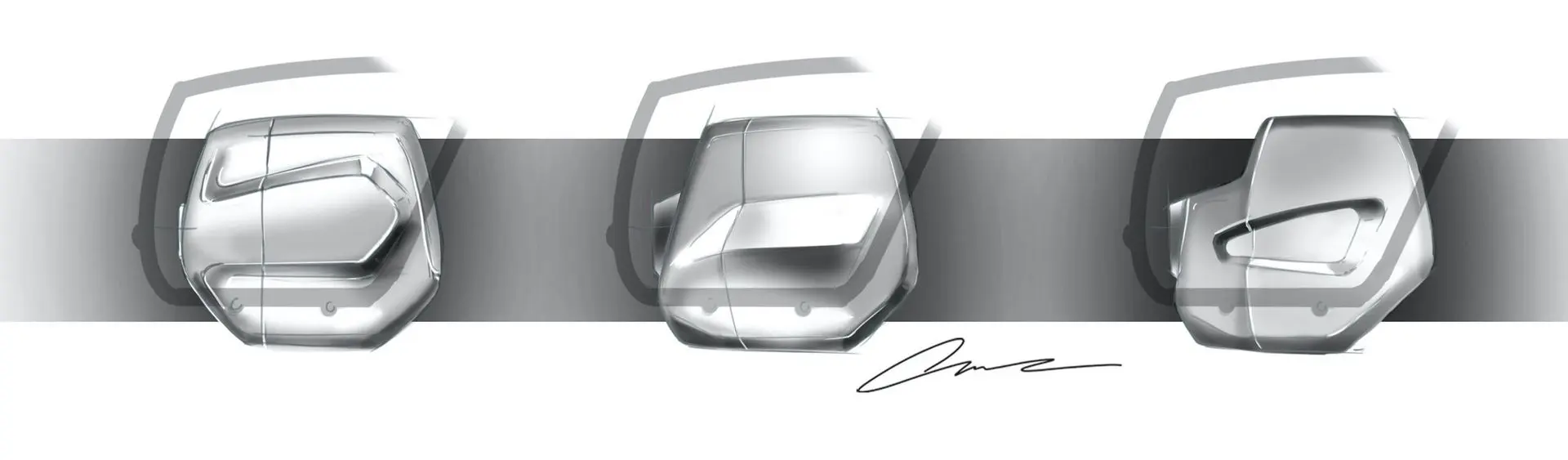

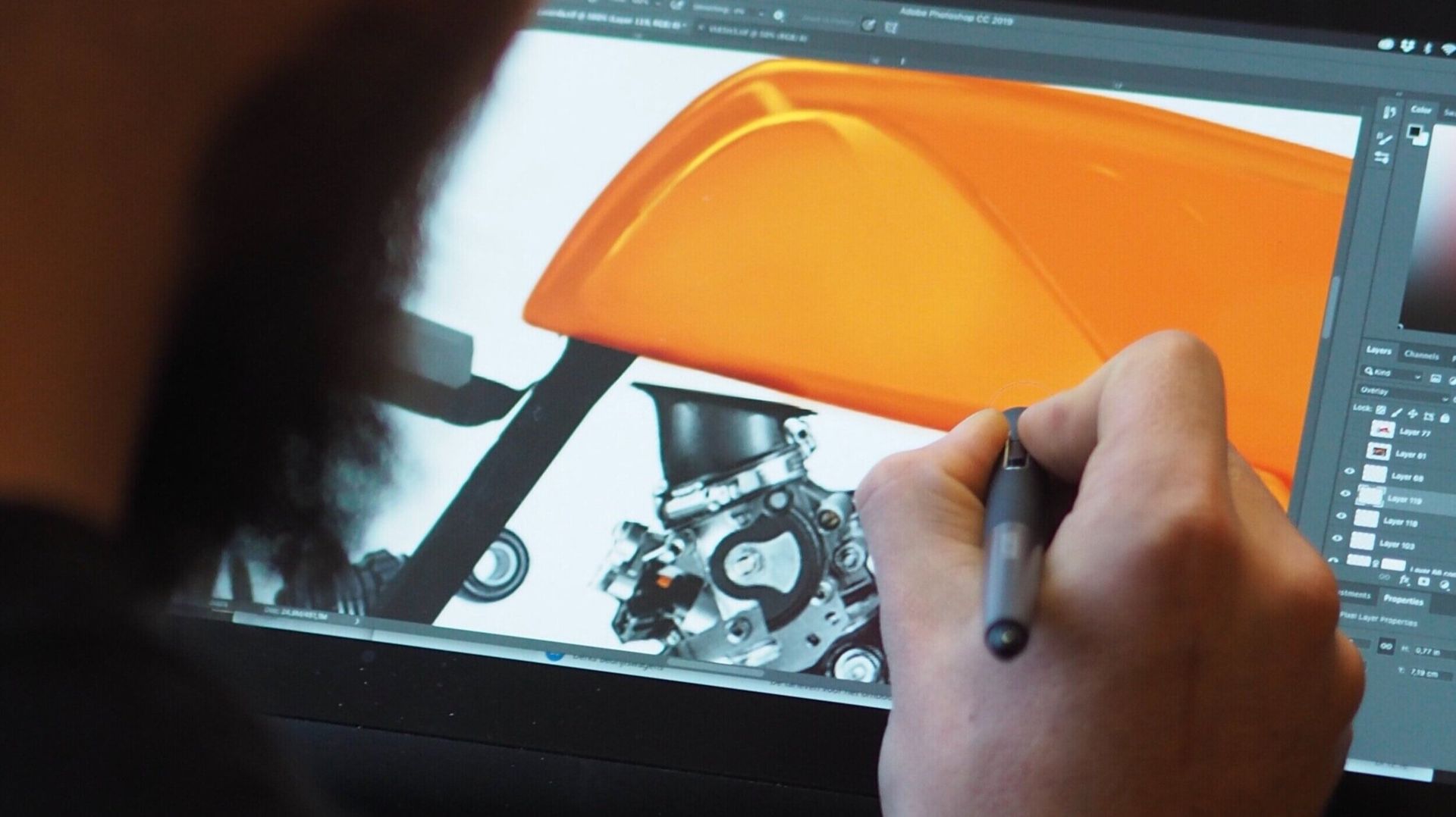

Design

Every great product starts with an idea. Whether you want to conceptualize a new product, refine a prototype, or enhance an existing design, there is always a way to bring your vision to life.

Design possibilities are endless, and we offer a range of services, including:

- Conceptual drawings to visualize ideas

- Problem-solving for product challenges

- Merging function with aesthetics

- Developing the next generation of your product

- Branding design for products and companies

- Visualizing graphic designs on products and marketing materials

- Enhancing services and concepts

If you need assistance with any of these design challenges, or have a unique idea in mind, we are here to find the right solution. By thinking outside the box and prioritizing your needs, we create designs that are both innovative and sustainable.

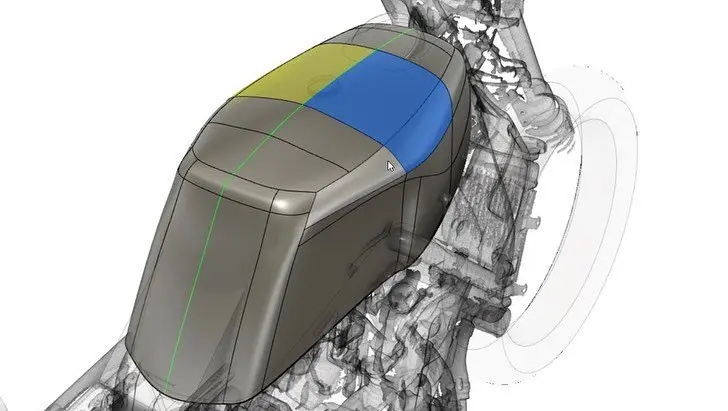

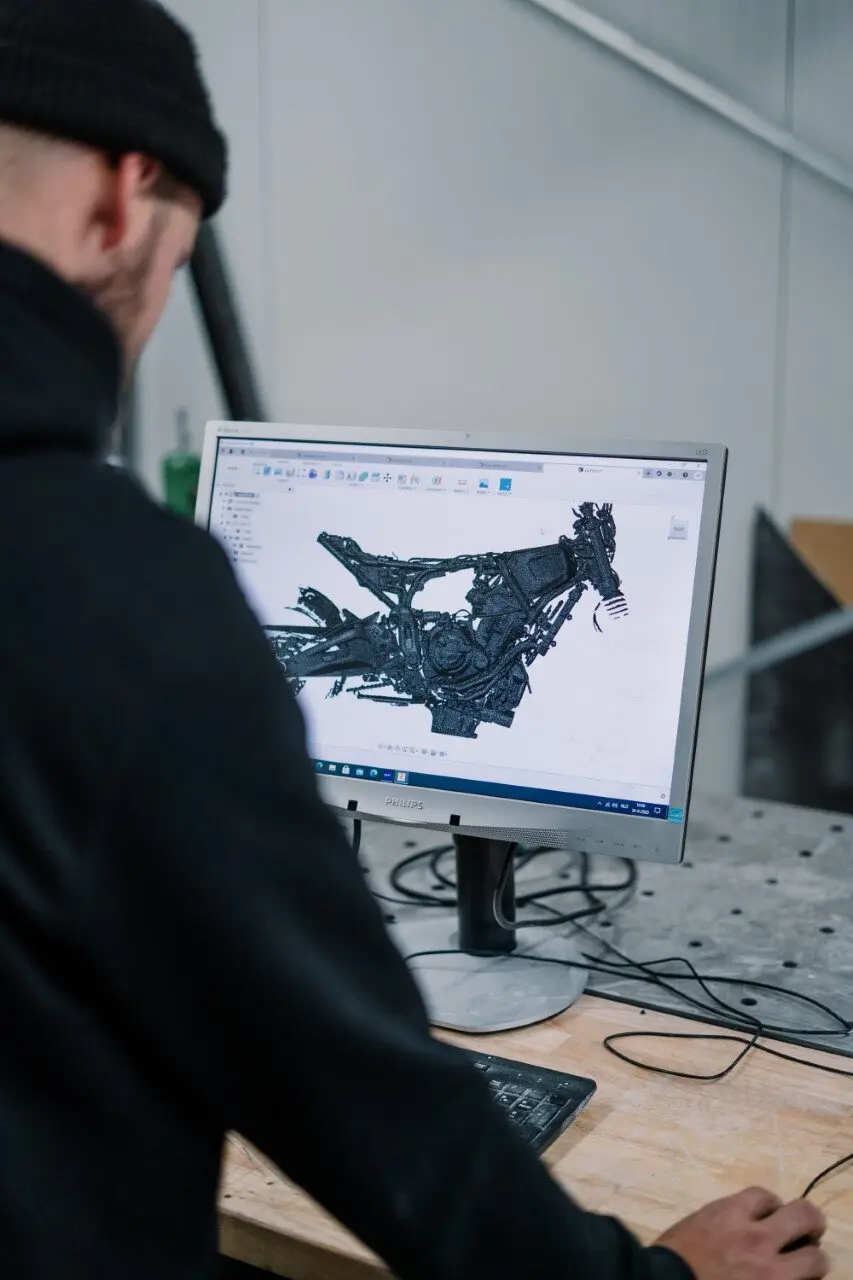

Engineering

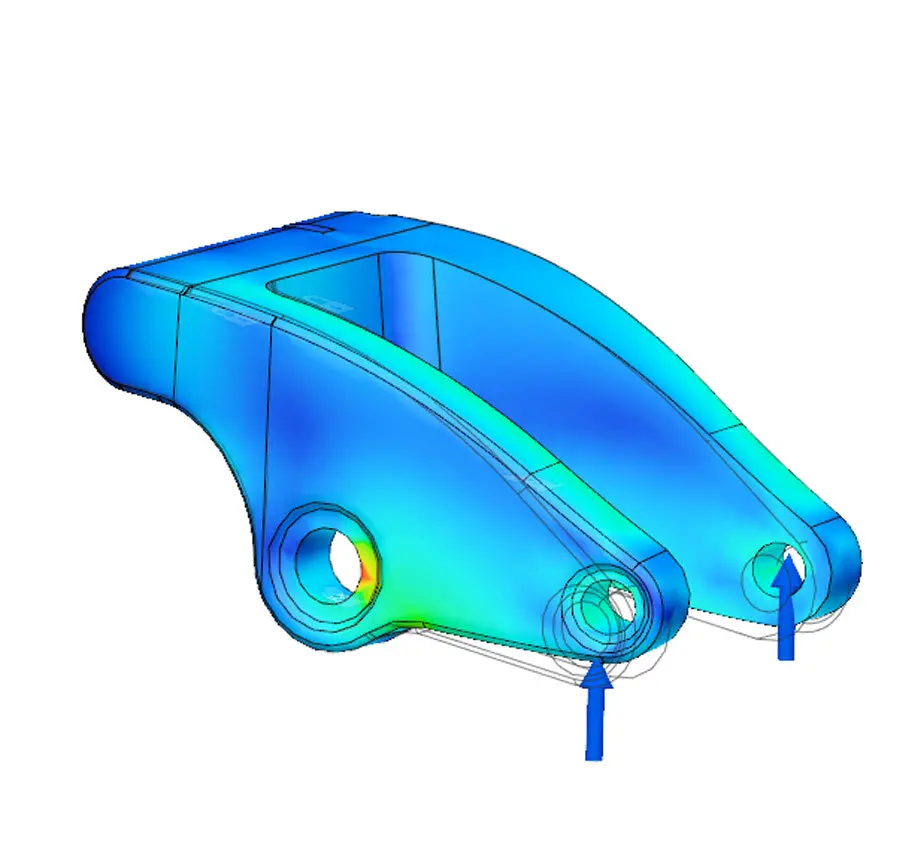

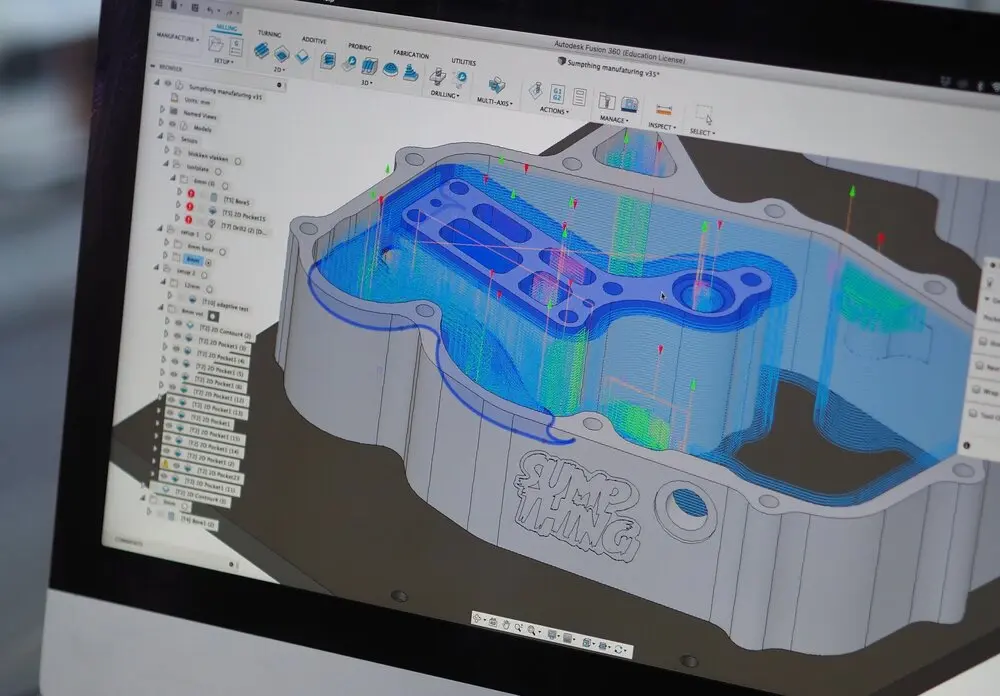

Engineering transforms ideas into reality, bridging the gap between design and production. Whether you need a 3D model of your concept, a CNC-ready prototype, or a fully engineered product for manufacturing, we provide the technical expertise to make it happen.

Engineering services include:

- Reverse engineering through high-precision 3D scanning

- Converting designs into production-ready models

- Integrating functionality with form

- Simulating and testing for product durability

- Preparing models for CNC fabrication

These are just a few of the ways engineering supports product development. LMC provides the expertise to refine, optimize, and produce your designs with precision and efficiency.

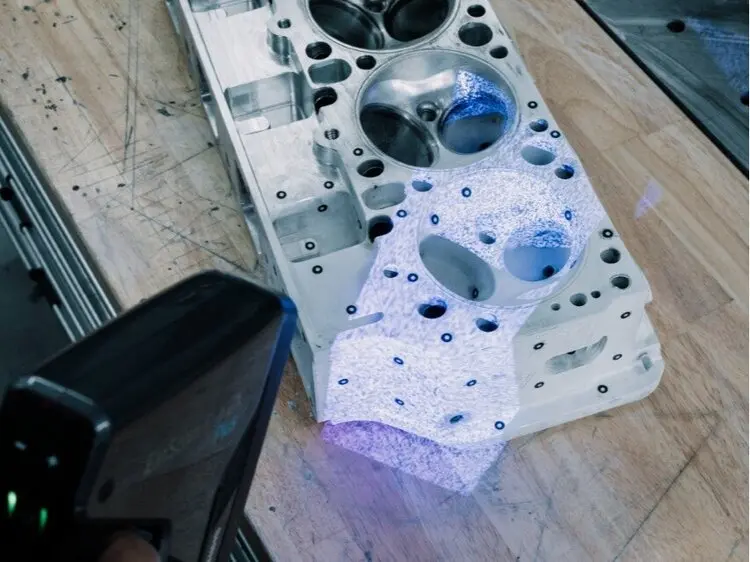

3D SCANNING

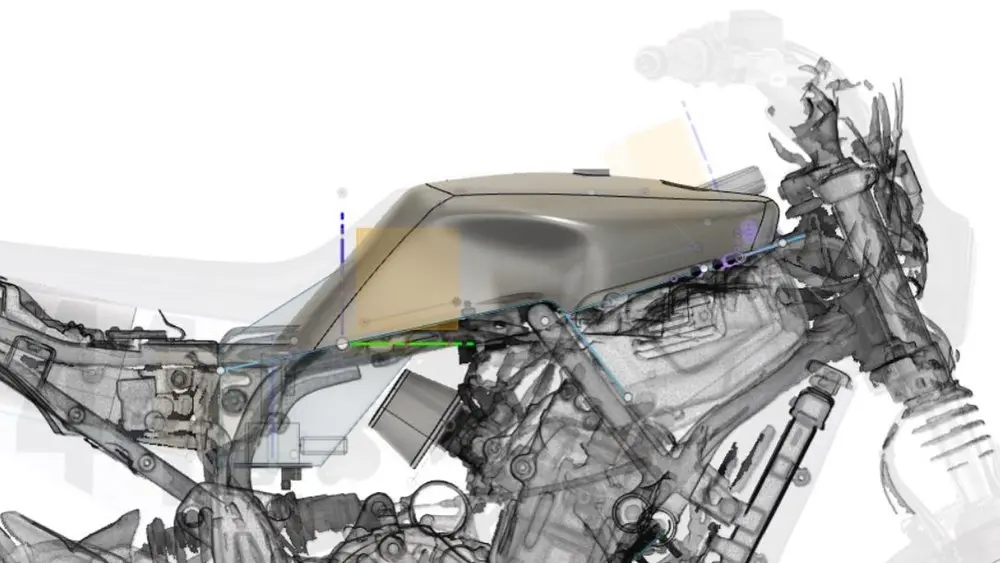

Revolutionary 3D Scanning for Precision Reverse Engineering

Since 2021, we have been offering a groundbreaking 3D scanning solution that enables effortless reverse engineering of objects of any size using the Einsan Einsan 3D scanner (click for more info).

Why Use 3D Scanning?

Many objects have complex geometries that are difficult or even impossible to measure using conventional methods. Take, for example, a V8 engine intake— with multiple ports and hard-to-reach areas, traditional measuring tools fall short. The same applies to a rocker arm, which lacks clear reference planes for accurate measurements. In such cases, 3D scanning is the most efficient and precise solution.

High-Precision Scanning & Engineering

Once a 3D scan is completed, we generate a high-resolution mesh file with an accuracy of up to 0.02 mm, depending on the scan method and settings. This mesh can be used to:

- Convert the scan into a fully functional 3D engineering file

- Serve as a reference to design new parts that interact seamlessly with the scanned component

Pricing & Contact

Pricing is based on object size. For example, scanning an object 200x200x200 mm costs approximately €200 (excl. VAT).

Interested in high-precision 3D scanning? Get in touch today!

Realization

Bringing a design to life requires the right expertise, materials, and production techniques. Whether you need a one-off prototype or small-batch production, we offer a full range of fabrication methods, including 3D printing in end use materials, engineered components, and hand-fabricated products.

Our capabilities include:

- Assembly

- Welding

- Metalworking

- Sheet metal fabrication

- Milling

- Turning

- Lay-up techniques

- 3D printing

- Coating

- Woodworking

After the design and engineering phase, the next step is prototyping and production. With in-house 3D printing, fabrication, and small-batch production, we can develop functional prototypes and manufacture custom parts. Additionally, our network of trusted partners allows us to scale production and provide the right solution from concept to final realization.

We also offer in-house 3D printing services, up to 500x500x500mm whether for prototypes or production parts designed by you or LMC. Send your request through our contact page for a tailored quotation.